our services

We Are A Pumps Provider Company

Deepa Engineering Works is based in the industrial city of Kanpur in the state of Uttar Pradesh. The factory is built on 1990 square meter area having all infrastructure facility Like air, water with 100 KVA electric power connections and 100 KVA diesel generating sets for interrupted power supply.

Pumps & Production

Our Pumps

We have facility for the developing complex steel cores for the stators, jigs and fixtures for better productivity level and for making of wooden pattern for the purpose of casting.

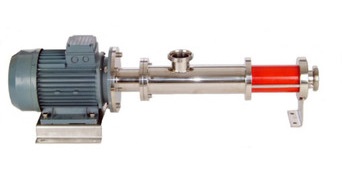

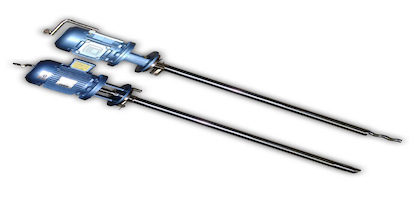

Industrial & Chemical Progressive Cavity Pump

Hygienic food grade Progressive Cavity Pump

Wide throatProgressive Cavity Pump

Metering Pump

BARREL & DRUM EMPITY PUMP

Dosing Wobble Pump

Rotor

Right material conforming to international standards combined with special heat treatment and hard chrome plating technology, Ensures dimensions and critical tolerances are maintained.

Quality Progressive cavity pumps , we have a wide range of retrofit spares to offer for brands like NETZSCH®, Roto pump®, psp, and other global brands as well.

Manufacturing materials :

✓ Stainless Steel.

✓ Hardened Carbon Steel.

Joint parts

Full range of coupling rods, shafts, universal joint kits are also available for all brands.

Coating options :

Hard chrome plating, chrome and special hard coatings.

The surface of the rotating parts, which are in contact with the product, is specially machined and treated with hardening processes to obtain a high mechanical resistance minimizing the abrasion effects. Also, high precision tolerance measurements avoid unwanted clearances and axial pushing. This ultimately prevents early wear and tear from happening.

Manufacturing materials :

✓ Hardened material.

✓ Stainless Steel.

✓ Hardened Carbon Steel.

Stator

Send Request for information With over 25 years of experience at designing, manufacturing and supplying Excellent quality Progressive cavity pumps , we have a wide range of retrofit spares to offer for brands like NETZSCH®, Roto pump®, psp, and other global brands as well.

A Majority of customers have found DEEPA PUMPS stator to outperform the originals at a better value for money.

DEEPA PUMPS are also available for other helical trademark manufacturers.

Manufacturing materials :

✓ HNBR ✓ NR ✓ SBR ✓ BR ✓ EPDM

✓ CSM ✓ FKM ✓ White NBR

✓ White EPDM ✓ White CSM

Our Application

Mines

Construction

Paper& Pulp

Explosive

Veg Oil & Vanaspti Plant

Dairy & Confectioneries

Ceramic & Refectories

Cosmetics & Pharmaceuticals

Sewage & Waste Water Treatment Plant

Chemical, Dye, Paint & Petrochemicals

Beverages, Breweries & Winners

Fruit & Vegetable Process

Contact Us for Any Query

We Are Always their to help You

Contact

Other Services

Application

SPARES