Wide throatProgressive Cavity Pump

Pumps

Wide throatProgressive Cavity Pump

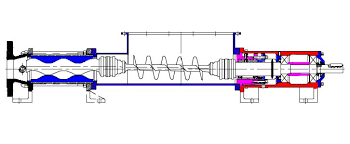

A Wide-Throat design ensures that the media enters the pump cavity easily by avoiding any clogging at the suction end , the Media flow ability is maintained using a screw conveyor better known as a ‘Augar’

EXPLODED PARTS

|

1. DELIVERY PIPE 2. TIE ROD 3. STATOR 4. PUMP HOUSING 5. INLET PIPE 6. ROTOR 7. BUSH |

8. BSR 9. BOOT SEAL 10. COUPLING PIN 11. COUPLING ROD 12. PRS 13. SHAFT 14. MECHANICAL SEAL/GLAND |

15. MECH. SEAL HSG/ STUFFING BOX 16. RUBBER RING/ SEAL RING 17. BODY/ BEARING HSG 18. GEAR BOX 19. ELECTRIC MOTOR 20. SUPPORT LEG 21. BASE PLATE |

Advantages and Characteristics

More Info

✓Steady, low-pulsation pumping

✓High self-priming rate

✓Installation possibilities in all positions

✓Direction of rotation and thus delivery flow reversible

✓Non-clogging: handles solids in suspension or mixture containing high percentage of solids.

✓Can work on Snore: inherently self-priming.

✓High Suction Lift: low NPSH(R), effective in high vacuum conditions.

✓Minimal Internal Wear: Gentle handling of shear sensitive and abrasive products because of low internal velocity.

✓Reversible: suction and delivery ends can be interchanged by merely changing direction of rotation of the prime mover.

WETTABLE HOUSING COMPONENTS :

• Fabricated Stainless Steel.

STATOR :

• Nitrile Black • Nitrile White • EPDM Black • EPDM White • Fluoroelastomer.

ROTOR :

• Stainless Steel.

COUPLING ROD :

• Stainless Steel.

SHAFT :

• Stainless Steel.

OTHER EXOTIC MATERIALS :

- Duplex • Super Duplex • Alloy 20 • Haste alloy.

Material options

More Info

WETTABLE HOUSING COMPONENTS :

• Fabricated Stainless Steel.

STATOR :

• Nitrile Black • Nitrile White • EPDM Black • EPDM White • Fluoroelastomer.

ROTOR :

• Stainless Steel.

COUPLING ROD :

• Stainless Steel.

SHAFT :

• Stainless Steel.

OTHER EXOTIC MATERIALS :

- Duplex • Super Duplex • Alloy 20 • Haste alloy.

FLUIDS HANDLED

| GYPSUM SLUDGE | CALCIUM CARBONATE SLURRY | BLEACHING CHEMICALS | SURFACTANTS |

| DETERGENTS | NEOPRENE-LATEX COMPOUND | PAPER MACHINE ADDITIVES | PULP STOCK |

| CAUSTIC | PHOTOGRAPHIC EMULSIONS | FLOCCULANTS | FILLERS LIKE: ALUMINUM SULPHATE, |

| LIQUORS | POLYESTER BLEND | OFFSHORE OIL PLATFORM TRANSFER | BENTONITE, RESIN SIZE AND CHINA/KAOLIN CLAY |

| OIL | RETAMINOL | LIME SLURRIES | THICKENER UNDERFLOW |

| CHEMICAL FEED AND METERING | POLYMER METERING | THICKENED DIGESTED SLUDGE | FILTER PRESS AND INCINERATOR FEED |

| CLAY SLIPS | TITANIUM DIOXIDE | ALUM TRANSFER | FILTER CAKE |

| PAINT | PARAFFIN | ACTIVATED SLUDGE | DEWATERING |

| FERTILIZERS | PAINTS AND INKS | SCUM AND GREASE | SAMPLING |

| INSECTICIDES | CLEANING SOLUTIONS | CHEMICAL METERING | SLUDGE TRANSFER |

| ADHESIVES | DEICING FLUIDS | FERRIC CHLORIDE | POLYMER INJECTION |

| AGRICULTURAL SPRAY WASH | EXPLOSIVES | COAL WATER | COAL OIL SLURRIES |

| ANTIFREEZE LUBRICANTS | HAZARDOUS WASTES | WASTEWATER | HIGH PRESSURE WASH |

| LATEX | PLASTIC | CLAY AND MINERAL SLURRIES | RECOVERY |

| AUGER FEED SCREW APPLICATIONS | GELS | TREATER BATTERY APPLICATIONS | POLYMER FLOODING |

| ACETONE | CALCIUM CARBONATE | MULTIPHASE FLUID TRANSFER | SKIMMED OIL |

| DISPERSION | FERRIC CHLORIDE | LATEX | FINE CHEMICAL MAKE DOWN SYSTEMS |

| COLORANTS | UREA | CHEMICAL METERING | MEDIUM CONSISTENCY PULP |

| ISOPROPANOL ALCOHOL | RUBBER | MILL WASTEWATER | CLAY SLURRIES |

| MAGNESIUM HYDROXIDE | LECITHIN | COATINGS | DEFOAMERS |

| PHENOLIC RESINS | METHANOL | COATING COLOR | TITANIUM DIOXIDE |

| PHOSPHATE | SODIUM CHLORIDE | STARCH SLURRY | CALCIUM CARBONATE |

| SPENT FILTER MEDIA/RESIN | ORGANIC COMPOUND | COOKED STARCH | RESIN |

| CORROSIVE CHEMICAL FEED | FLARE KNOCKOUT DRUM | HIGH PRESSURE SHOWER | CALCIUM STEARATE |

| SLUDGE | LUBE OIL | COATING KITCHEN CHEMICALS | COATING MACHINE PUMPS |

| OIL/WATER SEPARATION | CRUDE OIL AND WATER TRANSFER | DE-INKING CHEMICALS | PROPORTIONING SYSTEMS |

| DRILLING MUD TRANSFER |

Contact Us for Any Query

We Are Always their to help You

Contact

Other Services

Application

SPARES