Vertical Progressive Cavity Pump

Pumps

Vertical Progressive Cavity Pump

DPV & DPSV and DPHV Series vertical pumps are designed to operate with the pumping elements immersed in the product. These pumps are compact and space saving. They are custom designed and are manufactured for varying column length to suite the pump depth. The suction port of all the pump sizes is designed so that a strainer can be attached to prevent and large solids entering the pump.These pumps are available in only close coupled configuration. A variety of material of construction, shaft sealing options are also available.

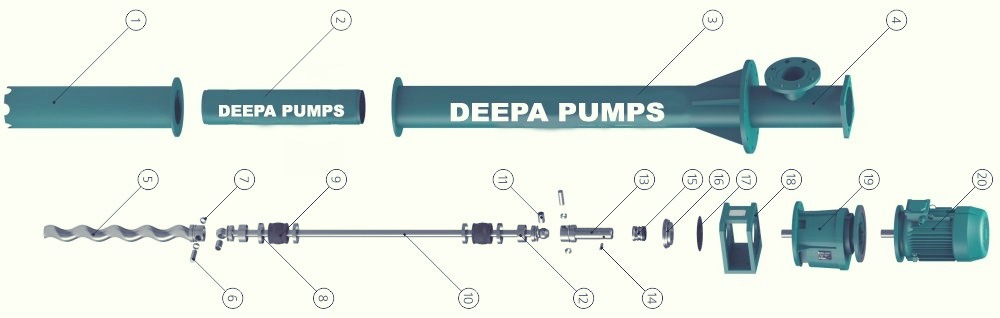

EXPLODED PARTS

| 1. SLEEVE

2. CLIP 3. BODY PIPE 4. DELIVERY PIPE 5. ROTOR 6. PIN 7. BUSH |

8. CONNECTING ROD

9. BOOTSEAL 10. CLAMP 11. C/ROD BUSH 12. PRS 13. YOKE SHAFT 14. SHAFT PIN |

15. MECHANICAL SEAL/ GLAND

16. MECH. SEAL HSG/ SUTFFING BOX 17. RUBBER RING/ SEAL RING 18. BODY 19. GEAR BOX 20. ELECTRIC MOTOR |

Technical Features

More Info

1. Patented joint due to its tested longer-life parts

✓ Robust configuration in high resistant hardened steel.

✓ Additional joint protection sleeve available.

✓ Compact: better mechanical performance, higher solids passage.

✓ Includes wear resistant coupling rod bush as standard.

✓ Better joint protection with new rubber sleeve design.

2. Rotor in induction deep hardening stainless steel as standard. Abrasion and corrosion resistance. It avoids the blade effect of chrome-coating. Other materials available for different applications. Wide range of sealing options. mechanical seals available.

3. Low and simple maintenance with only four wear parts: stator, rotor, coupling and mechanical seal.

Materials

More Info

• Fabricated Steel • Fabricated Stainless Steel.

STATOR :

• Natural • Nitrile • High Nitrile • EPDM • Chloro-Sulphonated Rubber • Fluoroelastomer • Aflas • HNBR

ROTOR :

• Tool Steel • Case Hardened Steel • Alloy Steel • Stainless Steel

COUPLING ROD :

• Alloy Steel • Stainless Steel

SHAFT :

• Alloy Steel • Stainless Steel

OTHER EXOTIC MATERIALS :

• Duplex • Super Duplex • Alloy 20 • Haste alloy

ROTOR SURFACE COATINGS :

• Ceramic Coatings • Tungsten Carbide • Hard Chrome Plating

PROTECTIVE COATINGS :

• Rubber Lining • Epoxy Coatings

Application

Contact Us for Any Query

We Are Always their to help You

Contact

Other Services

Application

SPARES